Industrial refrigeration

Specializing in Food and beverage refrigeration solutions

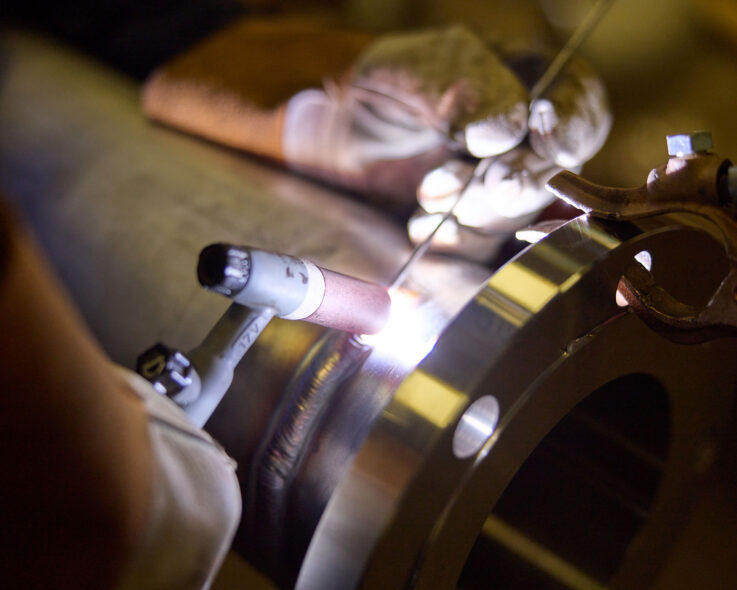

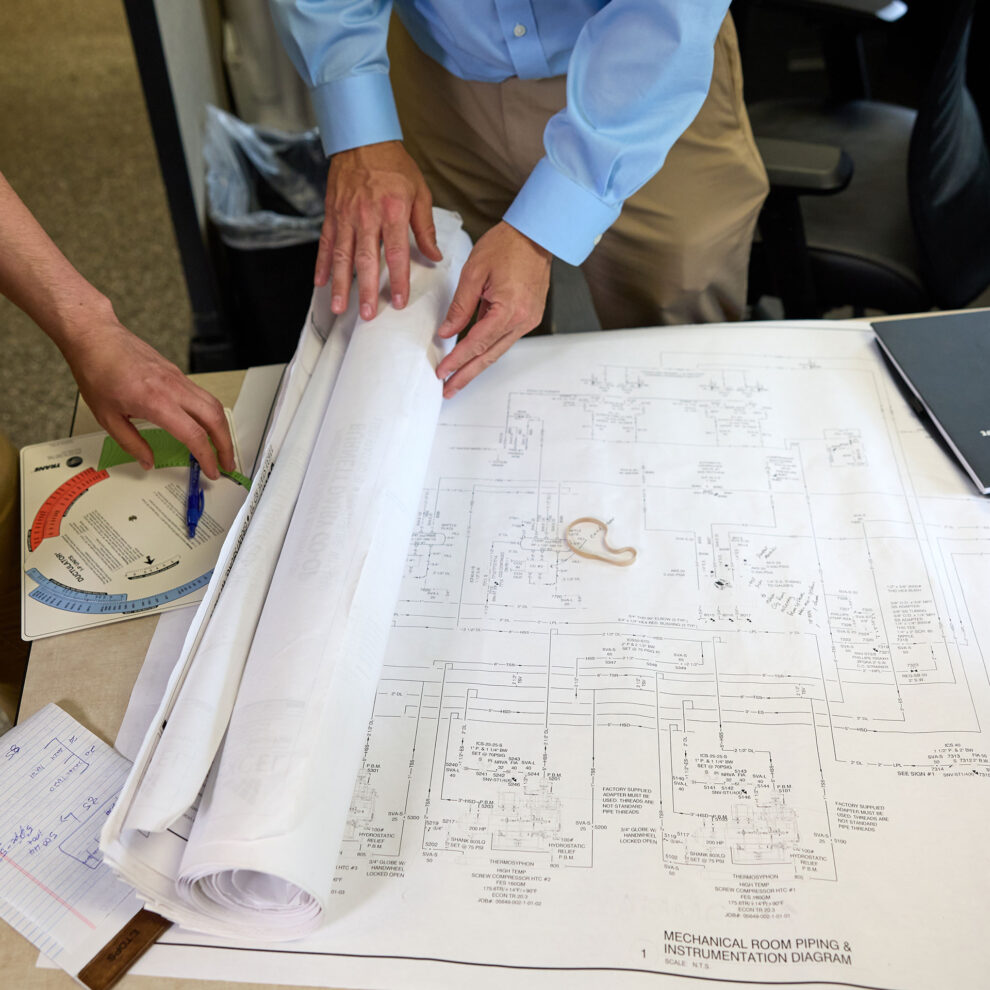

With a specialized emphasis on ammonia refrigeration solutions for industrial applications our team of experienced engineers can help you identify the best solution for your needs and apply them in the field. Aided with in-house drafting for projects our team is able to successfully install equipment with welded, carbon and stainless steel piping for any refrigeration project. A few common uses that apply to the ammonia food & industry are:

- Production Areas

- Loading Docks

- Cold Storage Spaces

- Spiral or Blast Freezing

- Fluid Cooling

- Ice Making

- Ice Rinks

A proven process to ensure your project’s success

At Cool Air Mechanical, we’re proud to have excellent systems that our team members rely on for each project. Because of this, we’re able to work on complex design/build projects, keeping things organized and on schedule. Our process, at a high level, is as follows:

Engineering consultation:

Because every project is unique, we start with an engineering consultation to ensure we have the proper understanding and capabilities to complete the project.

Proposal creation:

Once a thorough understanding of the project is identified, our team will work internally to create the most accurate proposal possible, providing you with clarity on cost and timeline.

Installation:

We then work with the General Contractor or business contact to schedule times for the work to be completed. Once installed, we’ll provide any necessary training or education to either the GC or business regarding how to use the equipment.

Servicing:

We don’t stop at installation. In many instances, our team works with our customers in an ongoing fashion, ensuring their equipment is maintained, and that they are protected from any unplanned downtime.

Cool Air Mechanical offers HAZWOPER training

HAZWOPER training teaches individuals how to investigate, and take care of an incident involving a hazardous chemical(s). In many cases, our team educates other contractors on how to follow this specific procedure, ensuring everyone involved remains safe. We offer two different types of training.

- 24 hour training course.

- Allows individuals to be certified for three years.

- 8 hour training refresher course.

- Allows individuals to be certified for one year.